Patching

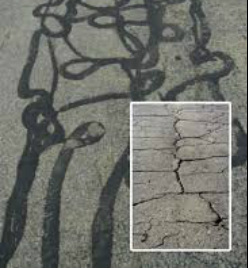

Example of an area that should NOT be crack sealed but patched.

Some areas just should not be crack filled and instead completely replaced.

A much more affordable and long term solution would be to use an infrared patching process that will give you an area which is sure to look better and last longer.

Some areas just should not be crack filled and instead completely replaced.

A much more affordable and long term solution would be to use an infrared patching process that will give you an area which is sure to look better and last longer.

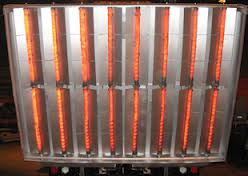

Below is a proper way to complete a patch.

The Bed is fueled with propane giving this bed plenty of heat to rework almost any blacktop or asphalt.

The bed is then laid over the blacktop until it is heated to a workable temp. Once the temp is reached the bed is lifted up and the raking begins.

Raking will loosen the old asphalt and make it workable again. Any debris that needs to be removed is taken out of the old asphalt. New asphalt is added to make sure the patch is level with the rest of the asphalt around it. The new asphalt added also replenishes some of the oils need for the asphalt to create a strong bond again when rolled back out.

The amount of asphalt added is determined by the patch ending up level.

The patch is than rolled smooth and ready to dive on when it cools to normal temp.

For holes and broken areas in your asphalt there is no better solution than our patching process other than replacing it. Seal coat can then be applied over the old asphalt as well as the new patch. This will blend the old asphalt with the new patch giving a nice finished look with out holes or busted up asphalt.